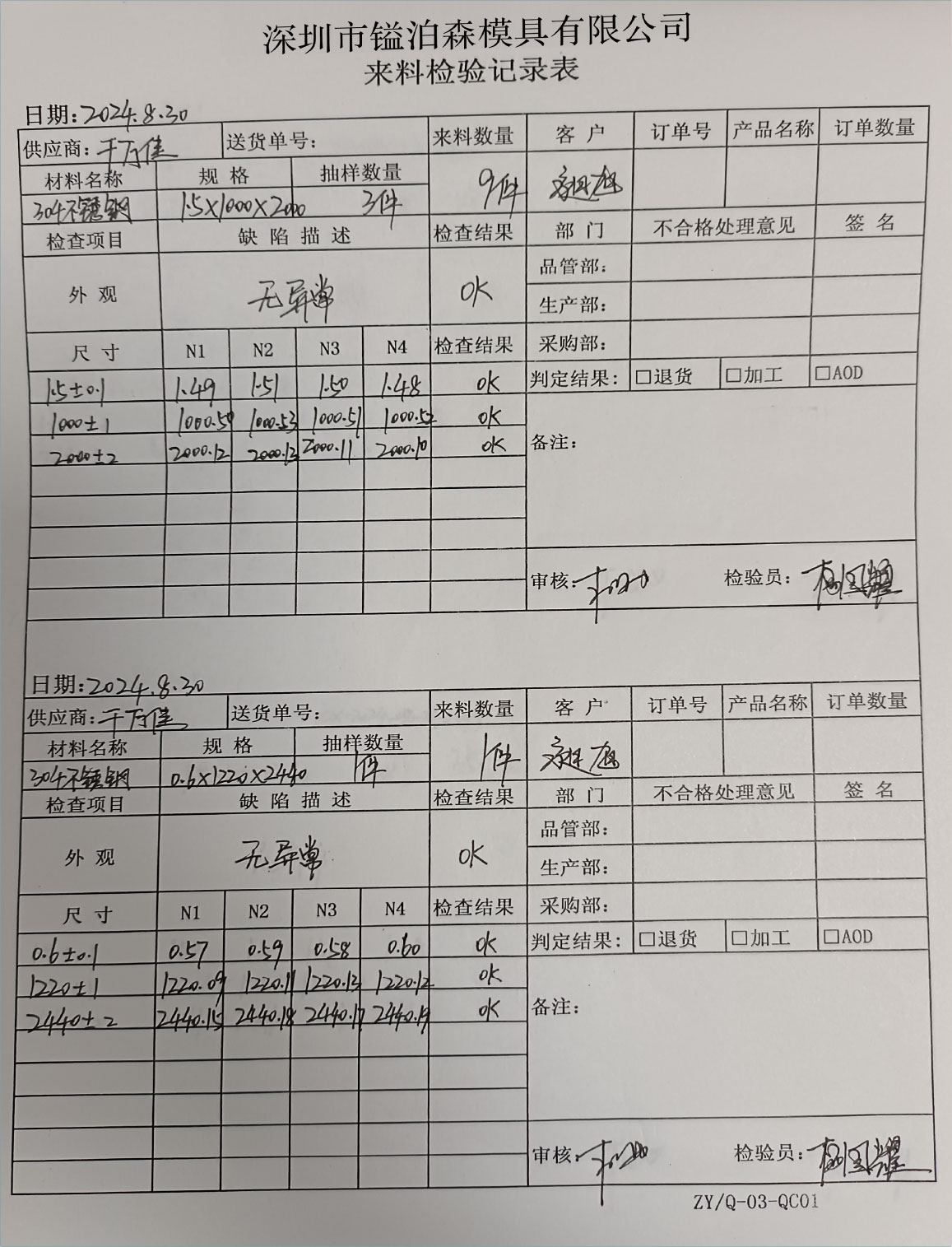

Raw material inspection report

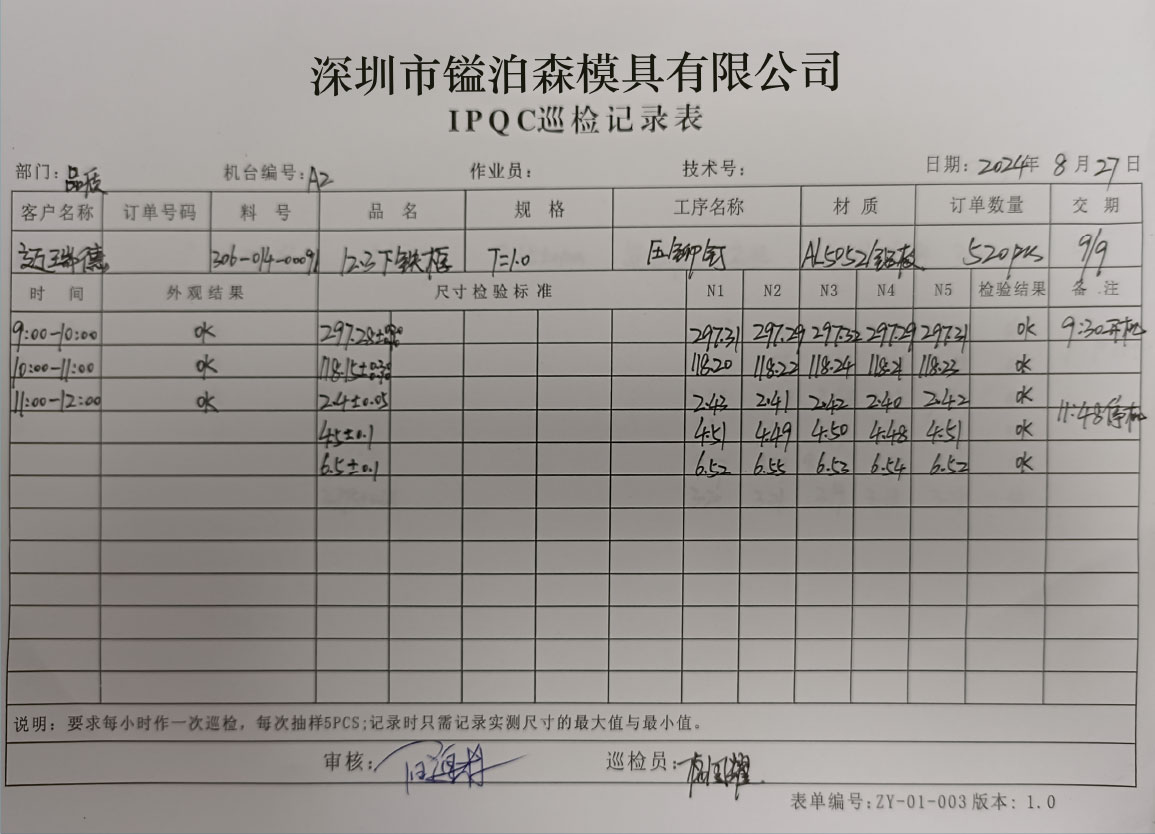

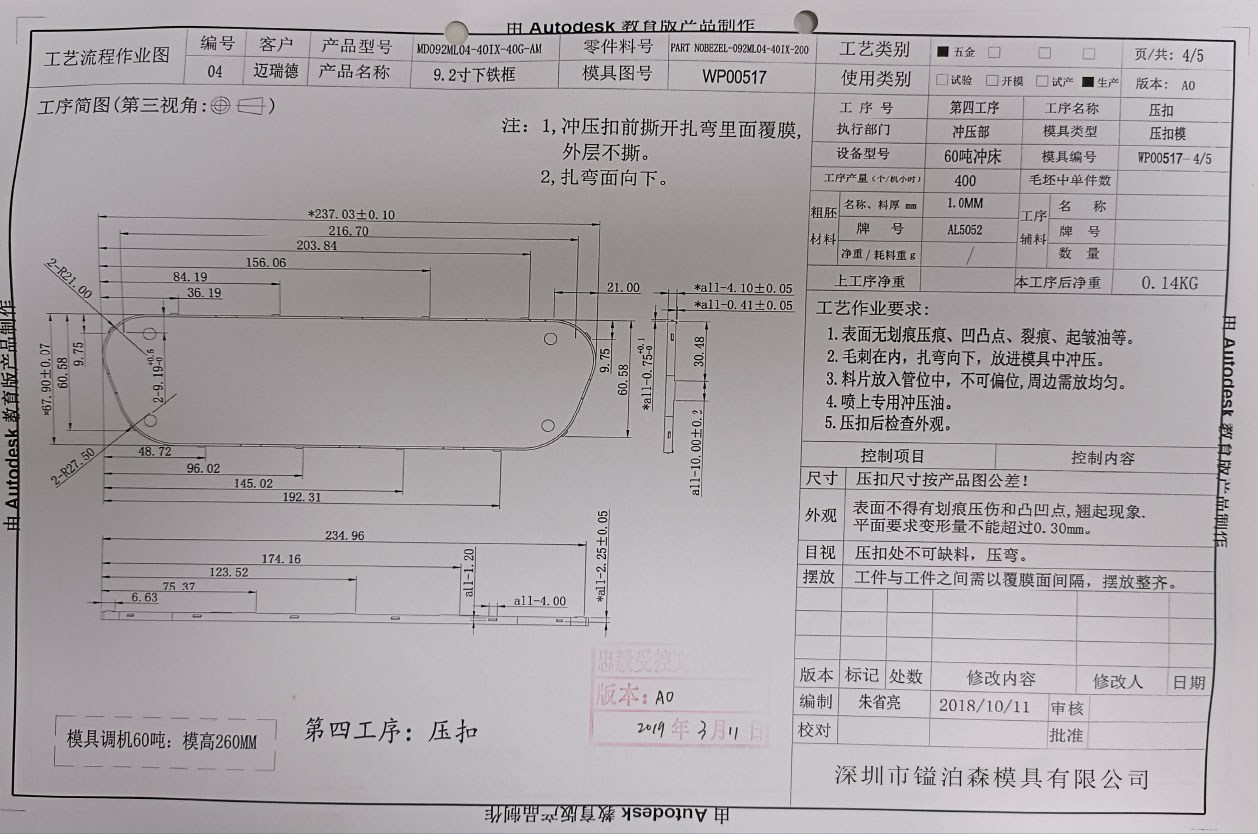

Production process specification

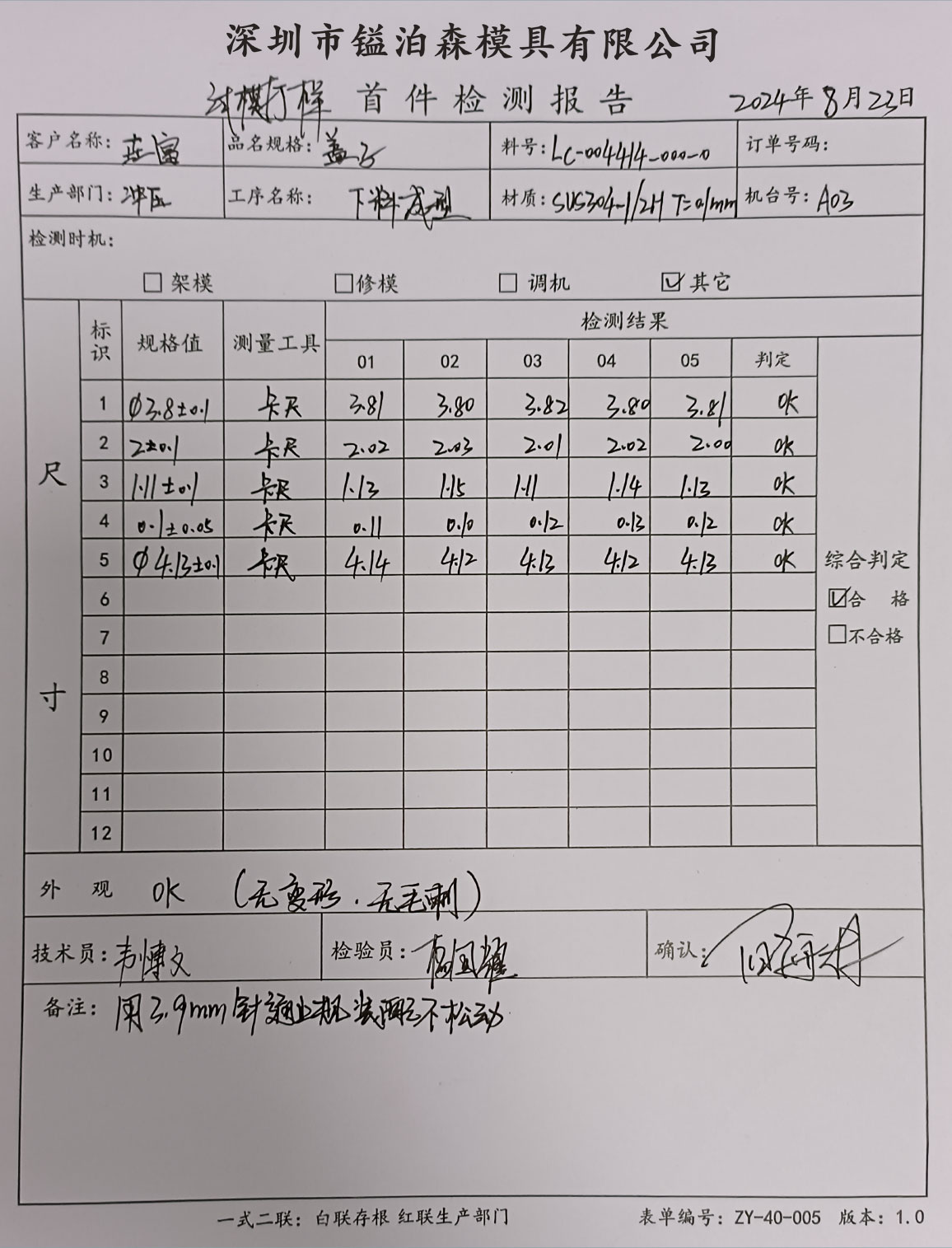

IPQC

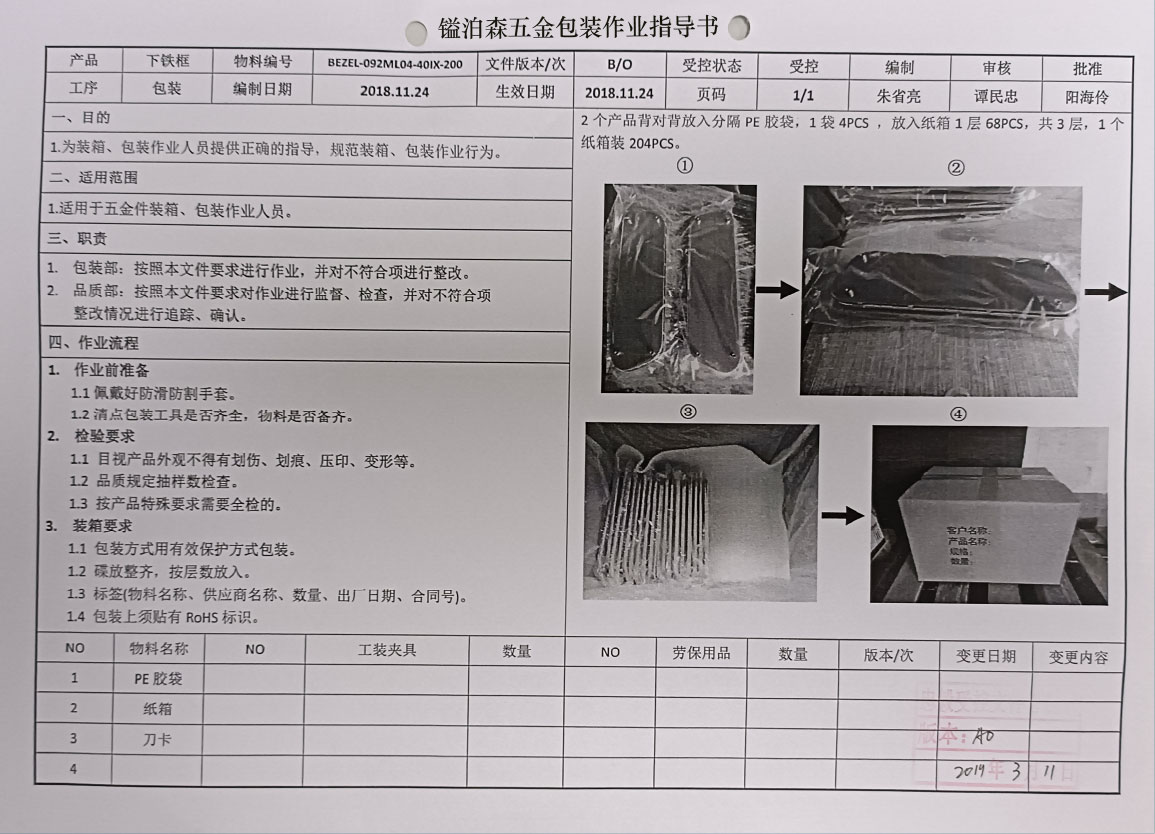

SOP

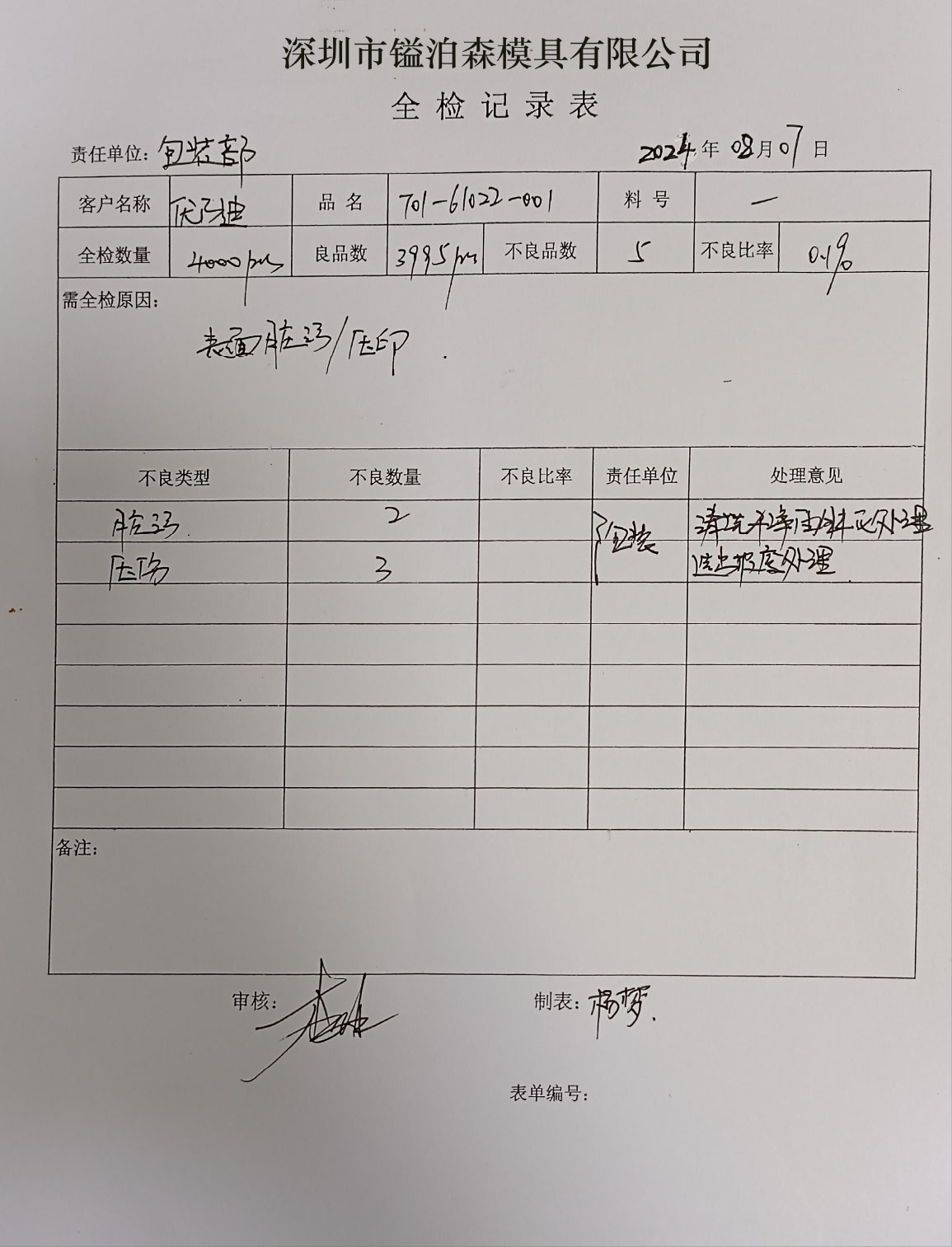

Full inspection report

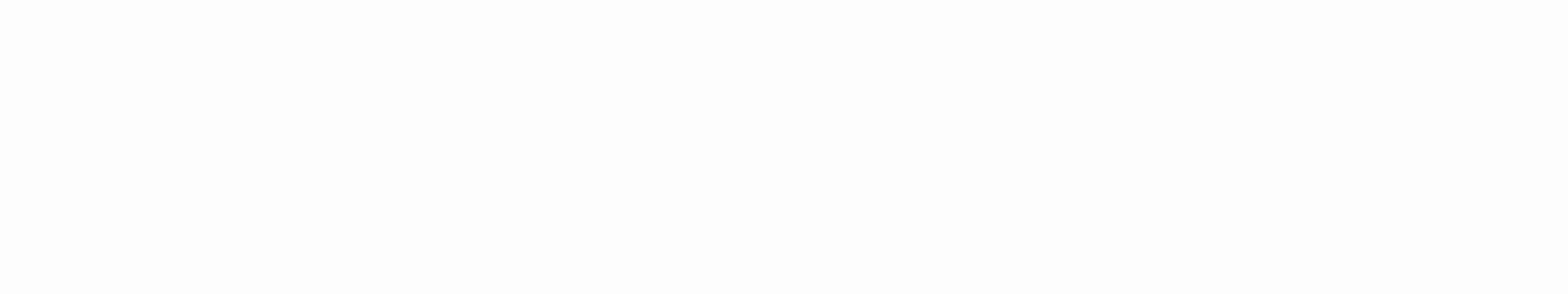

1st sample inspection

At EPPOSUN, quality excellence is our unwavering commitment. We believe that only through continuous improvement and rigorous quality control can we truly satisfy our end customers, foster long-term partnerships, and create lasting value for both our clients and our company. Our comprehensive quality management system oversees every stage of the production process—from material selection and tooling design to injection molding, assembly, and final inspection. Our facility is equipped with state-of-the-art testing and measurement instruments, including coordinate measuring machines (CMM), fully automated optical 2D inspection systems, RoHS analyzers, tensile testers, and HP-200 spectrophotometers for precise color evaluation. Every finished product undergoes 100% inspection to ensure the highest standards of precision, durability, and reliability, consistently achieving zero customer complaints and reinforcing EPPOSUN’s reputation for manufacturing excellence.

Quality

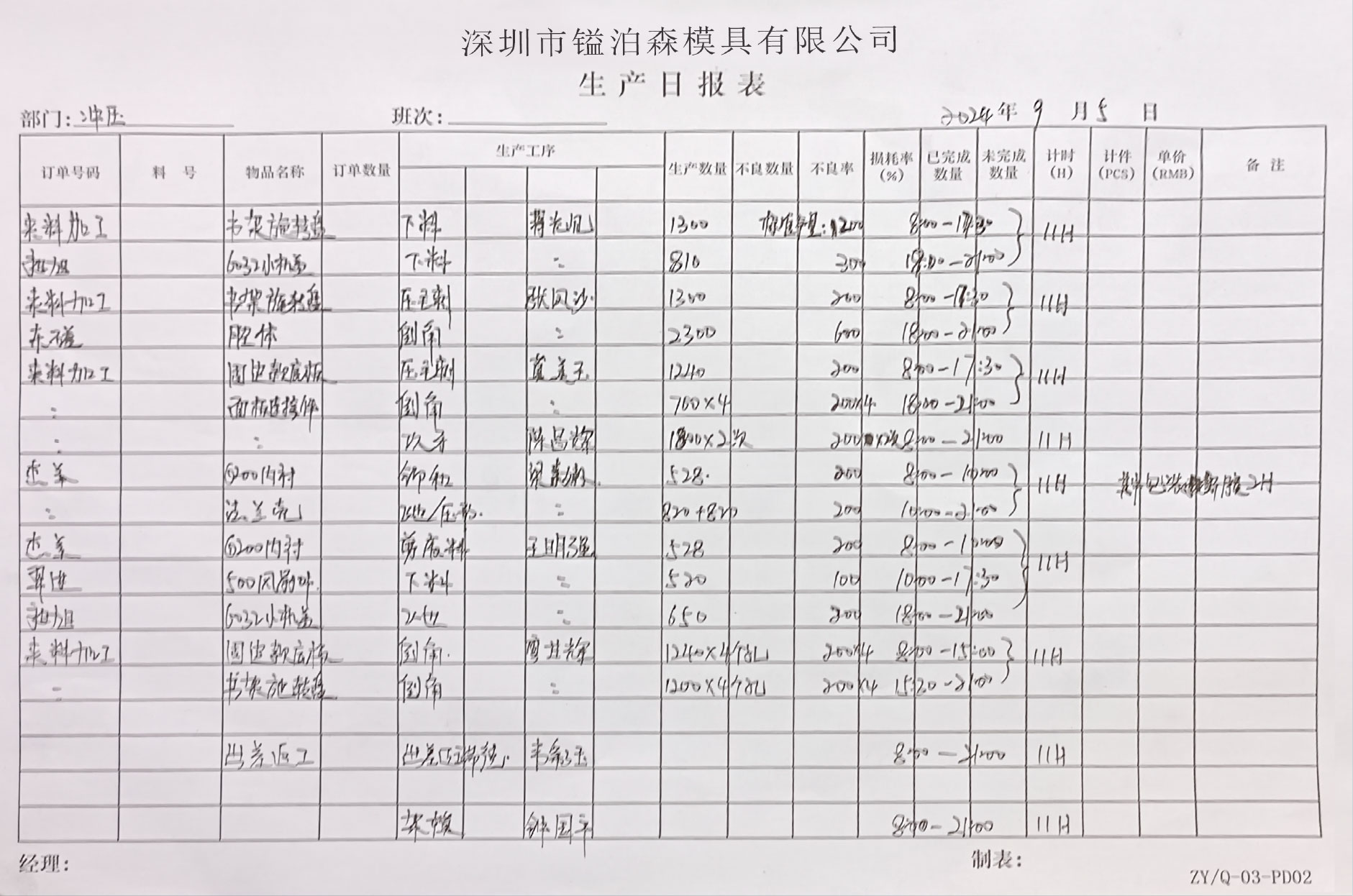

Production daily report

IPQC

Delivery & Quality Guarantee

At EPPOSUN, quality is implemented in accordance with ISO9001, ISO14001, and ISO13485 standards, with quality considerations integrated throughout every stage of product realization. In addition to ensuring product precision and reliability, we maintain strict schedule management, monitoring each process step to guarantee timely delivery. By combining rigorous quality control with effective time management, EPPOSUN ensures that every project meets both the highest quality standards and agreed-upon delivery timelines.

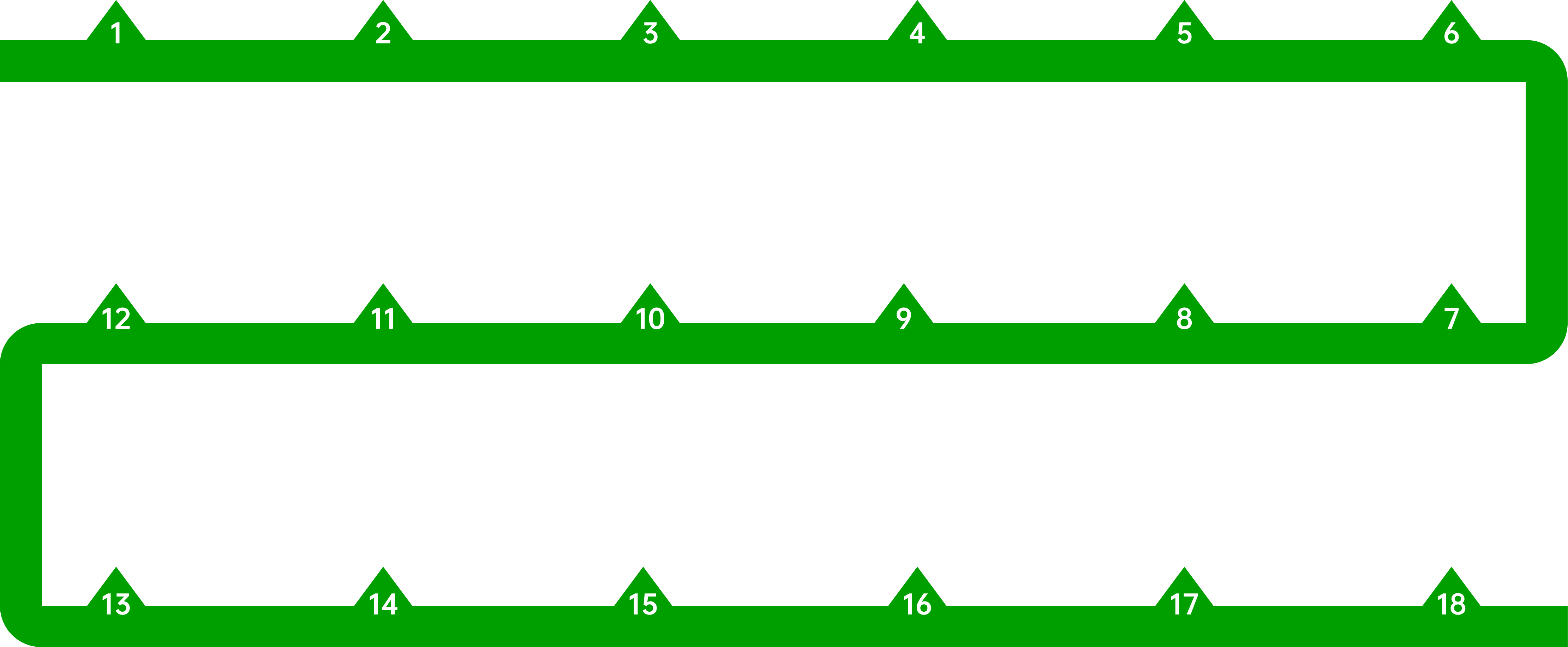

Quotation

Confirmation

New Project

Kickoff Review

DFM Review

Customer Approval of DFM & Design

3D Structure

Review

Customer Final 3D Model Approval

Production & Delivery Timeline Review

Customer Schedule Confirmation

QC Sample

Testing

Design Modification Review

Sample Approval

& Sign-off

Mold Inspection & Approval

First Article

(Batch) Inspection (FAI)

Sign-off of Production Samples

In-Process / Random QC Inspection

Final Pre-Shipment Inspection (PSI)

Product Delivery & Logistics

Incoming Material Inspection